Polyolefin Sponge

Product Name

Polyolefin Sponge

Polyolefin Sponge

Outline

Porous material made from PE/EVA. Resistance to strong acid and strong alkali. Various application for absorption, liquid retaining, wiping, and filtration.

Features

■Excellent chemical resistance. It's available to use under strong acid and strong alkali, also available to use under some oxidizing agent and organic solvent.

■Excellent absorption. It absorbs and retains solution because of its fine continuous pore structure.

■Because of sponge of integral structure, PO Sponge is free of any fray like nonwoven or felt.

■Because of its remarkable softness, PO Sponge Roller marvelously follows the contour of workpiece.

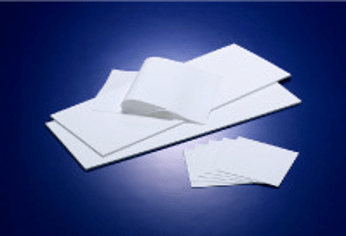

Polyolefin Sponge Sheet

Application

■Filtration & Absorption for gas and liquid

■Liquid Transfer

■Space for Electronic Parts

■Humid Coordination(Sublimation

■Ink Retainer & Supplier

■Wiping Material

Material

Physical Properties

Standard Size

| PE |

: |

300 x 500 x 1~7 mm |

| EVA |

: |

100 x 500 x 1~7 mm |

*Custom sizes are also available. Please contact us.

Chemicals Resistance

| *Testing Condition |

: |

Immersion for 2 weeks at room temperature (approximate 20℃). |

| *Judging Standard |

: |

○ = Strength Retention ≧ 80%, and Size Changing Rate < 5% |

|

|

△ = Strength Retention ≧ 60%, and Size Changing Rate < 10% |

|

|

× = Strength Retention < 60%, and Size Changing Rate ≧ 10% |

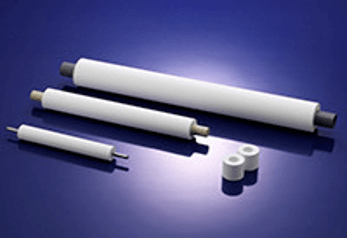

Polyolefin Sponge Roller

Application

■Liquid draining in plating and etching processes of printed-wiring boards, lead frames, etc.

■Liquid draining, conveyance, and application in manufacturing process of various components.

Material

Basic Physical Properties

*Basic Physical Properties are not be guaranteed, just for your reference.

Standard Size

| Outer Diameter |

: |

φ30 ~ 60 mm |

| Thickness |

: |

15 mm or less |

| Length |

: |

1000 mm or less |

(Dimensions listed above are only a part of our standard dimensions.)

( Please consult us about the custom sizes.)

Chemicals Resistance

| *Testing Condition |

: |

Immersion for 2 weeks at room temperature (approximate 20℃). |

| *Judging Standard |

: |

○ = Strength Retention ≧ 80%, and Size Changing Rate < 5% |

|

|

△ = Strength Retention ≧ 60%, and Size Changing Rate < 10% |

|

|

× = Strength Retention < 60%, and Size Changing Rate ≧ 10% |