Lithium-ion secondary battery production facilities

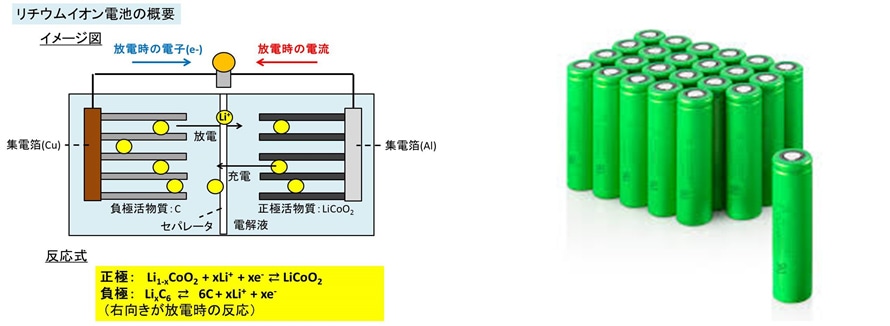

What is a lithium-ion secondary battery?

Lithium-ion rechargeable batteries are rechargeable batteries that are charged and discharged by lithium ions moving between the positive and negative electrodes. The materials used for the positive electrode, negative electrode, and electrolyte vary depending on the application and manufacturer. A typical construction is a lithium transition metal composite oxide for the positive electrode, a carbon material for the negative electrode, and a nonaqueous electrolyte such as an organic solvent for the electrolyte. They are simply called lithium-ion batteries, lithium-ion batteries, Li-ion cells, LIBs, and LiB.

Lithium-ion rechargeable batteries have superior features such as higher energy density, higher power density, and longer cycle life compared to other rechargeable batteries.

Lithium-ion secondary battery production facilities

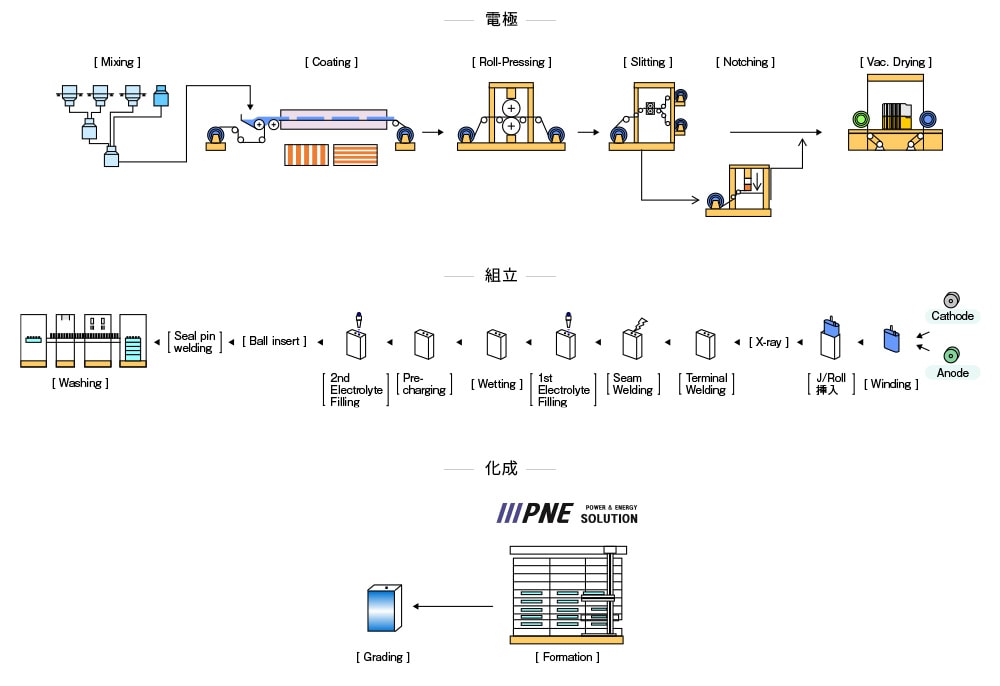

In the lithium-ion battery manufacturing process, the active material used as the electrode material is stirred, coated with aluminum foil, etc., and after being pressed into rolls, it is cut along its dimensions. Wind or laminate the finished electrode materials with insulating separators in between. Insert this into the case to assemble the batteries, pour electrolyte, seal the lid, and assemble the exterior. All of these are manufactured using unique equipment, including mixing equipment, coaters and coating machines, slitters, winders, stacking equipment, electrode assembly equipment, electrode plate winding equipment, battery assembly equipment, filling equipment, laser welding equipment, and exterior assembly equipment.

We provide comprehensive solutions with Korean equipment manufacturers, which have a proven track record, from the specifications, concepts, and designs of lithium-ion battery manufacturing equipment to manufacturing, installation, and trials, from the electrodes process to the final chemical production process.

Flow of Lithium Ion Battery Production Equipment

1.Electrode Process Equipment

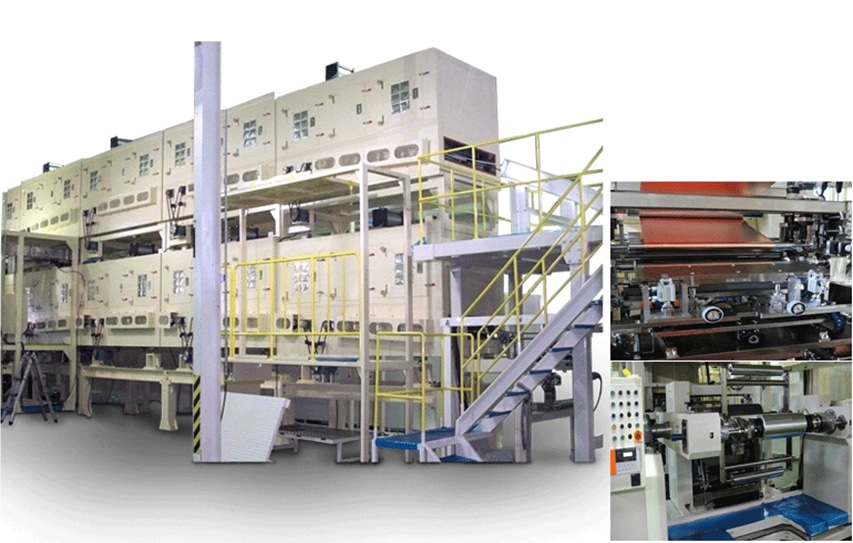

Lithium-ion secondary batteries are available in cylindrical, square, and pouch (laminate) types depending on the end use. The electrode manufacturing method and equipment used for the battery type vary. We are compatible with all battery types and provide comprehensive solutions through manufacturing line design to meet diverse customer needs.

Electrode manufacturing equipment (example)

Product specification

| Coating Width | Max.650mm |

|---|---|

| Coating Accuracy | ±1.5%(Dry) |

| Machine Speed | Max.650m/min |

| Drying Type | Roll Supporting Type |

| Coating Speed | 0.5-20m/min |

| Drying Zone | 3m×5zone×2Floor=30m |

| Coating Type | Micro Gravure Type |

| Heating Source | Electric Heater |

| Coating Mode | Continuous & Intermittent |

| Dimension | 35.0m(L)×5.8m(W)×6.0m(H) |

| Coating Thickness | Max.20㎛(One Side) |

| Delivery | 6Month |

2.Battery Assembly Equipment

Cylindrical Battery Manufacturing Equipment (Example)

Product specifications: Cells/Min

| TYPE | Available Capacity(Cells/Min) |

|---|---|

| 21700 | 150,200,220,300 |

| 18650 | 150,200,220,301 |

| Other | Customizing |

LINE AREA:6200cm×450cm250cm

Required Electric Powder:140kW

Vacuum:8m2/Min

Compressed Air:4m2/Min

3.Chemical Process Equipment (PNE SOLUTION))

Batteries that have been assembled are not designed to achieve 100% performance, even though they have been completed in terms of external dimensions. Cylindrical, square, and pouch (laminate) batteries must be charged and discharged during the formation process to improve battery performance. Batteries that have completed the conversion process exhibit stable capacity and output when they are used as modules with little variation in performance. Taking advantage of our experience in delivering batteries to major battery manufacturers, we provide high-efficiency, high-performance formation equipment that meets the diverse needs of our customers.

Product specification

| Detailed Items | Specification | |

|---|---|---|

| Interface | IEEE802.3(LAN) | |

| Controlling mode | CC, CV, CC/CV, OCV | |

| PC software | CTS Series | |

| Voltage | Error range | ±0.05%F.S |

| Precision | 16bit | |

| Electric current | Error range | ±0.1% |

| Precision | 16bit | |

| Current range per channel | Max. 2 ranges | |

| Control interval | 500/1000ms | |

| Time to reach current | <200ms (10% to 80% of specified value reached) |

|

| Input power-supply | Single-phase, 3-phase 220Vac 50/60Hz | |

・Current range: 100 mA to 600mA

・Multiple channels can be evaluated simultaneously

・Automated manufacturing in On-Line mode

Contact:

Battery Business Development Dept. (+81-3-3546-3319)