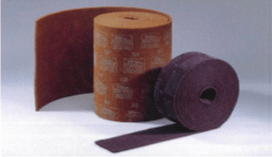

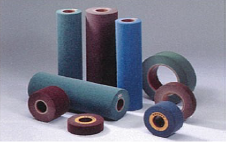

| Univex roll | : | Univex roll type. It can be cut and used freely according to the application. |

| Univex disc | : | A circle punched out of Univex. |

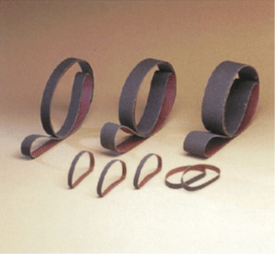

| Univex belt | : | A type of non-woven fabric with a net-like reinforcing material that is elastic and provides a uniform finish. |

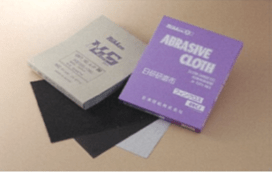

Abrasive Sheets, Discs, Tack Paper, etc.

Product Name

Abrasive Sheets, Discs, Tack Paper, etc.

Polishing Sheet

Waterproof Abrasive Paper Sheet

| WTCC-S | : | Water-resistant abrasive paper standard product, universal type for metal and woodwork painted surfaces, for both wet and dry use. |

| RRCC-S | : | Soft back type, ideal for hard wood coatings and metal coatings, for both dry and wet use. |

| WRAC-S | : | A abrasive product. Ideal for hard metal painted surfaces. |

Standard size 230 x 280

| Product type | Base material | Abrasive material | Grain size | ||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 60 | 80 | 100 | 120 | 150 | 180 | 220 | 240 | 280 | 320 | 360 | 400 | 500 | 600 | 800 | 1000 | 1200 | 1500 | 2000 | 2500 | 3000 | |||

| WTCC-S | Cw | CC | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ |

| RRCC-S | Cw | CC | ○ | ○ | ○ | ○ | ○ | ○ | |||||||||||||||

| WRAC-S | Cw | AA | ○ | ○ | ○ | ○ | ○ | ||||||||||||||||

Dry Abrasive Paper Sheet

| RRAC-SDS | : | Soft back type, ideal for dry sanding of coated surfaces that clog quickly. |

| AHAC-SDS | : | Boasts high polishing power using a strong and tenacious base material. Ideal for polishing wooden bases and painted surfaces. |

| FRCC-SDSS | : | For woodwork, curved painted surfaces, hand polishing of flat surfaces, and sanding. |

| FTCA-SDS | : | For hand polishing of woodwork, painted curved surfaces, and flat surfaces. |

Standard size 230 x 280

| Product type | Base material | Abrasive material | Grain size | ||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 60 | 80 | 100 | 120 | 150 | 180 | 220 | 240 | 280 | 320 | 360 | 400 | 500 | 600 | 800 | 1000 | 1200 | 1500 | 2000 | 2500 | 3000 | |||

| RRAC-SDS | Cw | AA | ○ | ○ | ○ | ○ | ○ | ||||||||||||||||

| AHAC-SDS | Cw | CC | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | |||||||||||

| FRCC-SDS | Cw | CC | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ||||||||||||

| FTCA-SDS | Aw | CC | ○ | ○ | ○ | ○ | ○ | ||||||||||||||||

Dry Polishing Cloth Sheet

| DRCJ-S | : | Excellent flexibility, ideal for polishing all curved surfaces. |

| DRCJ-SDS | : | Highly flexible, perfect for polishing all curved surfaces, anti-clogging product. |

| SGAJ-S | : | Glue cloth. A general polishing cloth sheet that can be used for a wide range of polishing. |

Standard size 230 x 280

| Product type | Base material | Abrasive material | Grain size | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 30 | 40 | 50 | 60 | 80 | 100 | 120 | 150 | 180 | 220 | 240 | 280 | 320 | 400 | 600 | |||

| DRCJ-S | Jw | AA | ○ | ○ | ○ | ||||||||||||

| DRCJ-SDS | Jw | CC | ○ | ○ | ○ | ○ | ○ | ||||||||||

| SGAJ-S | Jw | AA | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | * | ○ | * | ○ | ○ | |

Tack Paper

Dry Tack Paper (Glue Type Detachable Paper)

For sharpening. Anti-clogging product.

Peel off the liner paper with glue-type detachable paper, and use it by crimping it to a leather pad or the like.

| Product type | Base material | Abrasive material | Grain size | |||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 40 | 60 | 80 | 100 | 120 | 150 | 180 | 220 | 240 | 280 | 320 | 360 | 400 | 500 | 600 | 800 | 1000 | 1200 | 1500 | 2000 | |||

| DRAD-(R/D)DSN | Dw | AA | ★ | ★ | ★ | ★ | ★ | |||||||||||||||

| DRAC-(R/D)DSN | Cw | AA | ★ | ★ | ★ | |||||||||||||||||

| RRAC-(R/D)DSN | Cw | AA | ★ | ★ | ★ | ★ | ★ | ★ | ★ | |||||||||||||

*(R/D) in the product type is circular D or square R depending on the shape. There are sizes that cannot be manufactured with a star within the grain size.

*Please refer to the tack paper production example and inquire about the sizes that can be produced.

Magic Tack Paper (Magic Detachable Paper)

For sharpening. Anti-clogging product.

Magic type detachable paper makes it easy to replace the paper.

| Product type | Base material | Abrasive material | Grain size | |||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 40 | 60 | 80 | 100 | 120 | 150 | 180 | 220 | 240 | 280 | 320 | 360 | 400 | 500 | 600 | 800 | 1000 | 1200 | 1500 | 2000 | |||

| DRAD-(R/D)DSM | Dw | AA | ○ | ○ | ○ | ○ | ○ | |||||||||||||||

| DRAC-(R/D)DSM | Cw | AA | ○ | ○ | ○ | |||||||||||||||||

| RRAC-(R/D)DSM | Cw | AA | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ||||||||||||

| AHAC-(R/D)DSM | Cw | AA | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ||||||||||

*(R/D) in the product type is circular D or square R depending on the shape. There are sizes that cannot be manufactured with a star within the grain size.

*Please refer to the tack paper production example and inquire about the sizes that can be produced.

Film Magic Tack Paper (Magic Detachable Paper)

Abrasive paper with a film base that is ideal for polishing plastic surface of 2K type paint.

The smoothness and flexibility of the film base provide a highly precise finish.

Magic type detachable paper makes it easy to replace the paper.

| Product type | Base material | Abrasive material | Grain size | |||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 40 | 60 | 80 | 100 | 120 | 150 | 180 | 220 | 240 | 280 | 320 | 360 | 400 | 500 | 600 | 800 | 1000 | 1200 | 1500 | 2000 | |||

| WRAF-DDSM | FILM | AA | ★ | ★ | ★ | ★ | ★ | ★ | ★ | ★ | ||||||||||||

| WTCF-DDSM | FILM | CC | ★ | ★ | ||||||||||||||||||

*(R/D) in the product type is circular D or square R depending on the shape. There are sizes that cannot be manufactured with a star within the grain size.

*Please refer to the tack paper production example and inquire about the sizes that can be produced.

Example of Making Tack Paper (Magic Tack Paper/Dry Tack Paper)

Standard roll size

| Item | Width (mm) | Length (mm) |

|---|---|---|

| Magic tack roll | 75 | 15000 |

| 100 | ||

| 115 |

| Item | Grain size | Width (mm) | Length (mm) |

|---|---|---|---|

| New tack roll P-type |

#80~120 | 75 | 25000 |

| 100 | |||

| #150~400 | 75 | 40000 | |

| 100 |

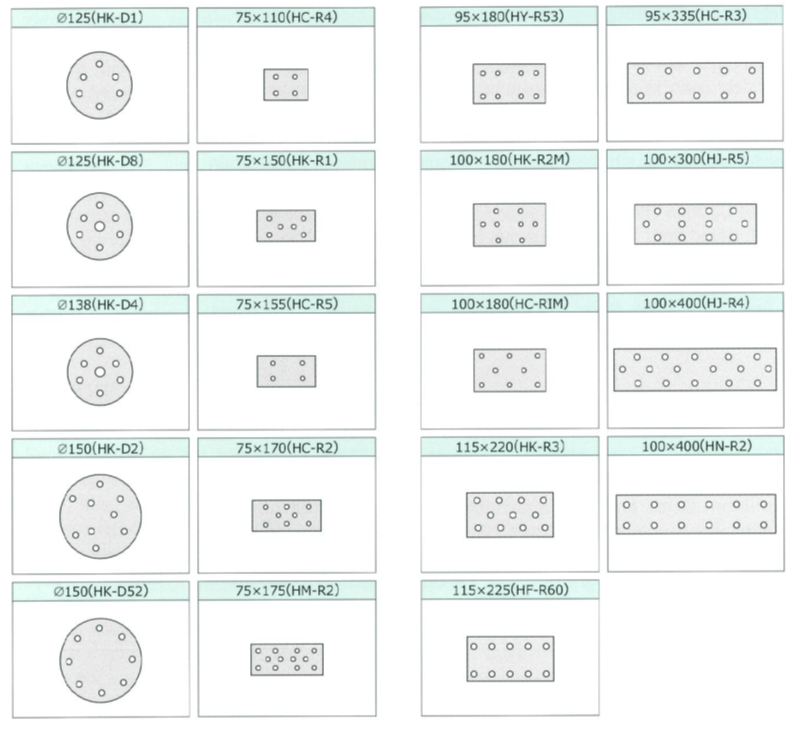

Examples of Punching Processing

Circular - no dust collection hole type 75φ、100φ、115φ、125φ、145φ、150φ etc.

Others:See below

Abrasive Belt

Abrasive Paper Belt (Mainly for Woodworking)

| WTCC-B(DS) | : | Standard product for polishing soft painted surfaces. |

| WRCC-B(DS) | : | For hard painted surfaces, high polishing power type. Highly resistant to moisture, heat, and durability. |

| WRWC-B(DS) | : | For finishing and polishing painted surfaces. Highly resistant to moisture, heat, and durability. |

| WRAC-B(DS) | : | For hard painted surfaces, high polishing power type. Highly resistant to moisture, heat, and durability. |

| DRCC-B(DS) | : | For polishing painted surfaces, high polishing power type. It has excellent heat resistance and is ideal for polishing hard painted surfaces. |

| DRWC-B(DS) | : | For polishing fabrics and painted surfaces. Good surface finish. Less clogging and more durable. |

| Product type | Base material | Abrasive material | Grain size | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 60 | 80 | 100 | 120 | 150 | 180 | 220 | 240 | 280 | 320 | 360 | 400 | 500 | 600 | 800 | 1000 | 1200 | |||

| WTCC-B(DS) | Cw | CC | ★ | ★ | ○ | ○ | ○ | ○ | ○ | ○ | ★ | ★ | |||||||

| WRCC-B(DS) | Cw | CC | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ||||||||||

| WRWC-B(DS) | Cw | WA | ○ | ||||||||||||||||

| WRAC-B(DS) | Cw | AA | ○ | ★ | ○ | ○ | ○ | ★ | |||||||||||

| DRCC-B(DS) | Cw | CC | ◆ | ○ | ○ | ○ | ○ | ◆ | ◆ | ||||||||||

| DRWC-B(DS) | Cw | WA | ○ | ○ | ○ | ○ | ○ | ◆ | |||||||||||

*Please contact us for available sizes.

*Both DS processed products and non-processed DS products are available for products marked with ○ in the grain size.

* DS processed products cannot be manufactured for products marked with ★ within the grain size.

* Only DS processed products can be manufactured for items marked ◆ within the grain size.

Abrasive Cloth Belt (Mainly for Woodworking)

| DRCJ-BDS | : | For polishing painted surfaces. Super flexible belt. |

| NRWJ-B(DS) | : | For polishing painted surfaces. Excellent durability of polishing power. |

| NRCJ-BDS | : | For polishing painted surfaces. Suitable for relatively hard painted surfaces. |

| PRWJ-B(DS) | : | For fabric polishing. Strong and flexible. |

| PRCJ-BDS | : | Finish polishing of the fabric. For polishing painted surfaces. Ideal for polishing curved surfaces with a profile sander. |

| SHWJ-B | : | Fabric finish polishing. For polishing painted surfaces. It has excellent polishing power and is ideal for polishing flat and curved surfaces. |

| SHWX-B | : | Fabric finish polishing. For polishing painted surfaces. Synthetic fiber base material used. Ideal for curved surface polishing. |

| DHWX-B | : | Standard product from rough polishing to finish polishing. There is little clogging and polishing burn is less likely to occur. |

| DRWX-B | : | For fabric polishing. Semi-open type. Ideal for polishing with an edge sander. |

| Product type | Base material | Abrasive material | Grain size | ||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 24 | 30 | 36 | 40 | 50 | 60 | 80 | 100 | 120 | 150 | 180 | 220 | 240 | 280 | 320 | 360 | 400 | 500 | 600 | 800 | 1000 | |||

| DRCJ-BDS | Jw | CC | ◆ | ◆ | ◆ | ◆ | |||||||||||||||||

| NRWJ-B(DS) | Jw | WA | ◆ | ◆ | ○ | ○ | ○ | ★ | ★ | ★ | |||||||||||||

| NRCJ-BDS | Jw | CC | ◆ | ◆ | ◆ | ◆ | |||||||||||||||||

| PRWJ-B(DS) | Jw | WA | ◆ | ○ | ○ | ○ | ○ | ○ | |||||||||||||||

| PRCJ-BDS | Jw | CC | ◆ | ◆ | ◆ | ◆ | ◆ | ◆ | |||||||||||||||

| SHWJ-B | Jw | WA | ★ | ★ | ★ | ★ | ★ | ★ | ★ | ★ | ★ | ★ | ★ | ★ | ★ | ||||||||

| SHWX-B | Xw | WA | ★ | ★ | ★ | ★ | ★ | ★ | ★ | ★ | |||||||||||||

| DHWX-B | Xw | WA | ★ | ★ | ★ | ★ | ★ | ★ | ★ | ★ | ★ | ★ | ★ | ||||||||||

| DRWX-B | Xw | WA | ★ | ★ | ★ | ★ | ★ | ★ | ★ | ★ | ★ | ★ | ★ | ||||||||||

*Please contact us for available sizes.

*Both DS processed products and non-processed DS products are available for products marked with ○ in the grain size.

* DS processed products cannot be manufactured for products marked with ★ within the grain size.

* Only DS processed products can be manufactured for items marked ◆ within the grain size.

Resin Cloth Belt (Mainly for Metal Applications)

| DRAX-B | : | Standard product for general metals. A wide range of work is possible from heavy grinding to polishing. |

| SRAJ-B | : | For general metal curved surface polishing. |

| WRAX-B S-23 | : | Wet standard product for general metals. A wide range of work is possible from heavy grinding to polishing. |

| FRAX-52-B | : | Standard product for special steel. A wide range of work is possible from heavy grinding to polishing. |

| DRCX-B | : | Standard product for polishing non-ferrous metals and glass. Suitable for grinding and polishing non-metals such as aluminum, copper and their alloys as well as glass. |

| NEWZ-B 02 | : | Exhibits free-cutting performance over a wide range, from heavy grinding of general steel to grinding and polishing of aluminum. |

| NEWZ-B 04 | : | Suitable for grinding and polishing difficult-to-cut materials such as stainless steel and titanium. |

| NEWZ-B 01 | : | Suitable for grinding and polishing difficult-to-cut materials such as stainless steel and titanium. It has good familiarity and is easy to use even with manual polishing. |

| DRSX-B 04 | : | Demonstrates excellent performance in heavy-duty grinding. Even for difficult grinding, there is little polishing burn and high polishing power is maintained. |

| Product type | Base material | Abrasive material | Grain size | ||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 24 | 30 | 36 | 40 | 50 | 60 | 80 | 100 | 120 | 150 | 180 | 220 | 240 | 280 | 320 | 360 | 400 | 500 | 600 | 800 | 1000 | |||

| DRAX-B | Xw | AA | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ||||||||

| SRAJ-B | Jw | AA | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ||||||||

| WRAX-B S-23 | Xw | AA | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ||||||||

| FRAX-52-B | Xw | AA | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ||||||||||

| DRCX-B | Xw | CC | ○ | ○ | ○ | ○ | ○ | ○ | |||||||||||||||

| NEWZ-B 02 | Xw | AZ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ||||||||||||||

| NEWZ-B 04 | Xw | AZ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ||||||||||||||

| NEWZ-B01 | Xw | AZ | ○ | ○ | ○ | ○ | ○ | ||||||||||||||||

| DRSX-B 04 | Xw | セラミック | ○ | ○ | ○ | ○ | ○ | ○ | |||||||||||||||

*Abrasive grain AZ: An abbreviation for alumina-zirconia abrasive grain, characterized by high grinding power due to its sharp grain shape and self-sharpening effect.

*Abrasive ceramics: High toughness, maintaining sharp grain shape, and unique crushing structure, resulting in sustained high grinding power.

*Please contact us for available sizes.

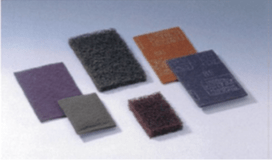

Non-woven Abrasive

Non-woven Abrasive Sheet

| Univex sheet | : | A sheet based on nylon non-woven fabric. Suitable for finishing fabrics and paintings. |

| Uniwool | : | Uses finer fibers than Unibex and is suitable for finishing woodworking and polishing uneven and curved metal surfaces. |

| Unisoft | : | A type in which a sponge is sandwiched between uniwool. Soft and familiar, it does not lose its shape until the end. |

| Unisand pad | : | Uses thicker fibers than Unibex. Excellent grinding power and durability, ideal for rust removal and descaling work. |

|

Unisand scrubber |

: | Household size of uni-sand pad. |

| 【Usage example】 | : | Removing rust and stains from press products Polishing of painted surface of woodworking field and lacquerware Hairline finishing of metal products |

| Product type | Size | Grain size | |||||

|---|---|---|---|---|---|---|---|

| M (#120equivalent) | F (#220equivalent) | VF (#400equivalent) | SM (#800equivalent) | SF (#1500equivalent) | UF (#3000equivalent) | ||

| Univex sheet NS | 150 x 230 | ○ | ○ | ○ | ○ | ○ | ○ |

| Product type | Size | Grain size | ||

|---|---|---|---|---|

| #800 | #1500 | #3000 | ||

| Uniwool | 150 x 230 | ○ | ○ | ○ |

| Unisoft | 150 x 115 | ○ | ○ | ○ |

| Product type | Size | Grain size | ||

|---|---|---|---|---|

| Rough (equivalent to #60) | Medium (equivalent to #80) | Fine (equivalent to #120) | ||

| Unisand pad | 150 x 250 | ○ | ○ | ○ |

| Unisand scrubber | 100 x 150 | ○ | ○ | ○ |

Non-woven Abrasive Rolls, Punched Discs, Belts

| Product type | Manufacturable size | Grain size | |||||

|---|---|---|---|---|---|---|---|

| M (#120equivalent) | F (#220equivalent) | VF (#400equivalent) | SM (#800equivalent) | SF (#1500equivalent) | UF (#3000equivalent) | ||

| Univex roll NR | Maximum width1000㍉ | ○ | ○ | ○ | ○ | ○ | ○ |

| Maximum length30m | |||||||

| Univex disc ND | 50Ф~355Ф | ○ | ○ | ○ | ○ | ○ | ○ |

| Univex Belt NTB | Please contact us | ○ | ○ | ○ | ○ | ○ | ○ |

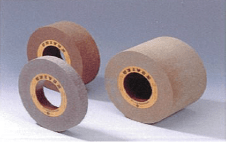

Univex Pressed Wheel

| Pressed Wheel NL | : | A product made by layering and compressing UNIVEX, which is characterized by its grinding power. |

| 【Usage examples】 | : | Groove polishing of aluminum sashes, scratch removal of electrical parts, small deburring of press products, etc. |

| Product type | Manufacturable size | Grain size | Hardness | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| M | F | VF | SM | SF | Hard | ← | → | Soft | |||

| NL | Outer diameter75~355 | ○ | ○ | ○ | ○ | ○ | N | O | P | Q | R |

| Thickness 10~60 | |||||||||||

(Unit: mm. Depending on the combination of size, width, grain size, and hardness, it may not be possible to manufacture.)

| Pressed wheel NLS | : | An upgraded version of NL with excellent dimensional accuracy. |

| 【Usage example】 | : | Precision groove polishing of woodwork, metal, etc. |

| Product type | Manufacturable size | Grain size | Hardness | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| M | F | VF | SM | SF | Hard | ← | → | Soft | |||

| NLS | Outer diameter75~355 | ○ | ○ | ○ | ○ | ○ | N | O | P | Q | R |

| Thickness3~100 | |||||||||||

(Unit: mm. Depending on the combination of size, width, grain size, and hardness, it may not be possible to manufacture.)

| Pressed wheel NLC | : | Features high grinding power and low wear, and has excellent cushioning properties. |

| 【Usage example】 | : | From removal of build-up to finishing of welded parts such as automobile window frames. |

| Product type | Manufacturable size | Grain size | Hardness | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| M | F | VF | SM | SF | Hard | ← | → | Soft | ||

| NLC | Outer diameter75~355 | ○ | ○ | ○ | ○ | ○ | 2Z | Z | H | M |

| Thickness3~60 | ||||||||||

(Unit: mm. Depending on the combination of size, width, grain size, and hardness, it may not be possible to manufacture.)

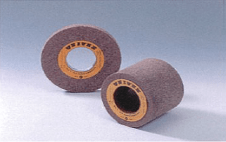

Univex Spiral Wheel

| Spiral wheel NBP | : | A product made by winding Univex spirally around a bake pipe and infiltrating it with a special resin. |

| 【Usage example】 | : | Aluminum panel base and hairline finish, various polishing work in the woodworking field, etc. |

| Product type | Manufacturable size | Grain size | Hardness | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| M | F | VF | SM | SF | Hard | ← | → | Soft | |||

| NBP | Outer diameter150~305 | ○ | ○ | ○ | ○ | ○ | HS | H | M | ||

| Thickness10~200 | |||||||||||

(Unit: mm. Depending on the combination of size, width, grain size, and hardness, it may not be possible to manufacture.)

| Spiral wheel NBW | : | A product that takes advantage of the moderate elasticity of NBP to improve polishing power. |

| 【Usage example】 | : | Aluminum panel base and hairline finish, various polishing work in the woodworking field, etc. |

| Product type | Manufacturable size | Grain size | Hardness | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| M | F | VF | Hard | ← | → | Soft | |||||

| NBW | Outer diameter150~305 | ○ | ○ | ○ | HS | H | M | ||||

| Thickness10~200 | |||||||||||

(Unit: mm. Depending on the combination of size, width, grain size, and hardness, it may not be possible to manufacture.)

Univex Flap Wheel

| Flap Wheel NHH | : | A product in which Univex is radially adhered to a bake pipe, which generates less heat during polishing and is durable. |

| 【Examples of use】 | : | Hairline finishing of stainless-steel bathtubs and sinks, various polishing work in the woodworking field, etc. |

| Product type | Manufacturable size | Grain size | Hardness | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| M | F | VF | SM | SF | UF | Hard | ← | → | Soft | |||

| NH | Outer diameter150~405 | ○ | ○ | ○ | ○ | ○ | ○ | HS | H | M | ||

| Thickness20~1600 | ||||||||||||

(Unit: mm. Depending on the combination of size, width, grain size, and hardness, it may not be possible to manufacture.)

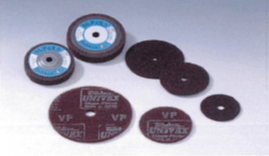

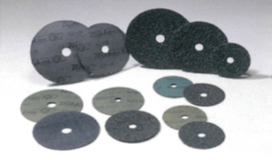

Abrasive Disc

Fiber Disc

| HCA | : | Hard type for heavy grinding such as steel plate surface polishing of hulls and car bodies. Back side white. |

| FCA | : | Standard type for general polishing. Backside is green. |

| BAA(BAN) | : | Soft type for polishing curved surfaces and finishing before painting. |

| BAN-F | : | Excellent heat dissipation due to the flower shape. |

| TAN | : | A multi-layer coating type with abrasive grains for outstanding durability. |

| Product type | Abrasive material | Dimensions mm | Grain size | Remarks | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Product code | Outer diameter | Hole diameter | 12 | 14 | 16 | 20 | 24 | 30 | 36 | 40 | 50 | 60 | 80 | 100 | 120 | 150 | ||

| HCA | CC | 100 | 15.9 | ○ | ○ | ○ | ○ | ○ | ||||||||||

| 125 | 15.9 | ○ | ○ | ○ | ○ | ○ | ||||||||||||

| 150 | 19.1 | ○ | ○ | ○ | ○ | ○ | ||||||||||||

| 180 | 22.2 | ○ | ○ | ○ | ○ | ○ | ||||||||||||

| FCA | CC | 100 | 15.9 | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ||

| 125 | 15.9 | ★ | ○ | ○ | ★ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ||||

| 150 | 19.1 | ★ | ★ | ○ | ★ | ○ | ★ | ○ | ★ | ★ | ○ | ○ | ★ | ★ | ||||

| 180 | 22.2 | ○ | ○ | ○ | ★ | ★ | ○ | ★ | ○ | ○ | ★ | ○ | ||||||

| BAA (BAN) |

AA | 100 | 15.9 | ☆ | ★ | ★ | ★ | ★ | ★ | |||||||||

| 125 | 15.9 | ★ | ★ | ★ | ★ | ★ | ||||||||||||

| 150 | 15.9 | ★ | ★ | ★ | ★ | ★ | ||||||||||||

| 19.1 | ★ | ★ | ★ | ★ | ★ | |||||||||||||

| 22.2 | ★ | ★ | ★ | ★ | ★ | |||||||||||||

| 180 | 22.2 | ★ | ★ | ★ | ★ | ★ | ||||||||||||

| BAN-F | AA | 125 | 15.9 | ★ | Flower shape | |||||||||||||

| 150 | 19.1 | ★ | Flower shape | |||||||||||||||

| 180 | 22.2 | ★ | Flower shape | |||||||||||||||

| TAN | AA | 100 | 15.9 | |||||||||||||||

| 125 | 15.9 | |||||||||||||||||

| 150 | 15.9 | ★ | ★ | ★ | ||||||||||||||

| 19.1 | ★ | ★ | ★ | |||||||||||||||

| 22.2 | ★ | ★ | ★ | |||||||||||||||

| 180 | 15.9 | ★ | TAN-8H type only | |||||||||||||||

| 19.1 | ★ | ★ | ★ | |||||||||||||||

Items marked with ○ are standard stock items.

Items marked with ★ are usually made-to-order products.

Items marked with ☆ are standard stock items for BAN type only.