MPR Pitting Tester

Product Name

MPR Pitting Tester

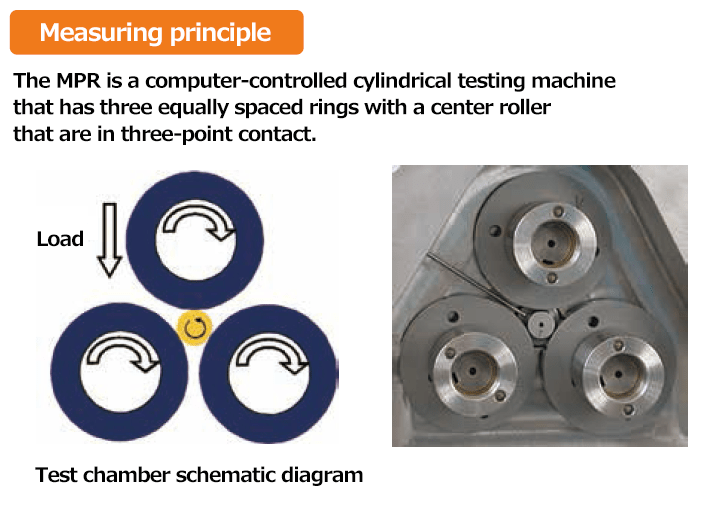

Fatigue wear test is reproduced by three-point contact ring and roller. Ideal for rolling fatigue, micro-pitting, and macro-pitting evaluations. The test is automatically stopped when the piezoelectric accelerometer detects vibration during pitting.

*Click here to download more detailed materials (English/Japanese)➡ *Japanese website

Overview

- Reproduce fatigue wear test with 3 cylinders.

- Ideal for rolling fatigue, macro-pitting, and micro-pitting evaluations.

- The test is automatically stopped when pitching is detected by the accelerometer.

Characteristics

- Pitting is generated in a short time using three rings and one center roller, and the time until pitting occurs is measured by verifying vibration with an accelerometer.

- The ring and center roller are driven by independent DC servomotors, making it possible to reproduce a Slide/Roll ratio of 0 to ±200%.

- At any time during the test, the test can be interrupted, the center roller removed, the contact surface observed, and the test resumed.

- The optional oil cooler cools down the test chamber after the test, making it possible to shorten the cleaning time.

Specification

|

Load |

100 – 1250N |

|---|---|

|

Speed |

Up to 4000 mm/sec (depending on Slide/Roll ratio) |

|

Slide/Roll ratio |

0% (pure rolling) to +/-200% (pure sliding) |

|

Temperature |

Ambient to 135℃ (below-ambient with optional cooler) |

|

Test sample volume |

150 ml |

|

Maximum roller torque |

20Nm(with 3-point contact) |

|

Power supply |

200~240V AC, 50/60Hz Max3.0kW(15A) |

|

Dimensions |

Top plate open 660mm(w) × 1300mm(d) × 1880mm(h) |

|

Weight |

295kg |

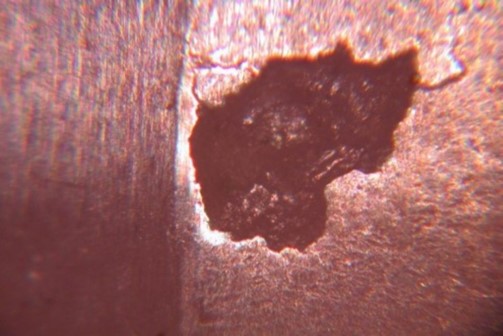

Pitting

Pitting is a rolling contact fatigue failure mechanism that occurs in periodically stressed mechanical components such as gears, cams and rolling bearings.

Micro-pitting is fine pitting that occurs on the contact surface due to plastic flow on the surface roughness caused by repeated cyclic contact stress. Macro-pitting is large pitting that occurs on the contacting surfaces as cracks initiated at or below the surface propagate into the pitting, and tend to occur at highly loaded contacts more than micro-pitting.

Ring Test Piece and Center Roller Test Piece

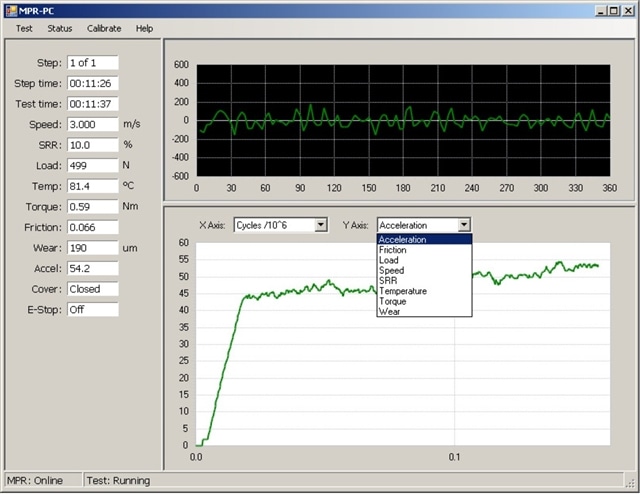

Software

Displays a graph with X and Y axes that can be changed at the top and a graph of the accelerometer (can be hidden) at the bottom.