Circular Track Meter (CT meter)

ASTM:E-2157-01

Product Name

Circular Track Meter (CT meter)

ASTM:E-2157-01

This is a road surface roughness meter using a CCD laser displacement sensor. The DF tester is designed to measure the roughness of the road surface along the measurement circular locus used to measure the coefficient of dynamic friction. There are several ways to express the roughness of the road surface, but the CT meter expresses it as MPD (Mean Profile Depth), which can be used in combination with the DF tester to calculate the IFI (International Friction Index).

Characteristics

●Time required for measurement is short and handling is easy. Used by connecting to a PC.

●It is easy to carry and can be transported by van, pickup truck, or SUV.

●The measured value represents MPD and has good reproducibility.

●Measurement is easy and there are no individual differences.

●Uses 12V DC power supply. AC/DC converter available. (AC/DC converter sold separately.)

●With one measurement, it is possible to obtain four types of data: the running direction of the road surface, the direction perpendicular to the running direction, the direction at 45°to the running direction, and the entire circumference.

Appropriate Road Surface

●Paved surfaces such as sidewalks and motorways

●Floor materials for buildings, etc.

●Floors for common areas of condominiums, etc.

●Floors of sports facilities such as gymnasiums

●Other surfaces

Measuring Principle

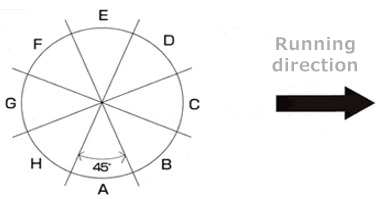

Sampling one rotation is 1,024 (892 mm), divide these measured values into 8 sections from A to H, and calculate MPD for each.

Taking the average of A and E in the 8 sections gives the MPD in the running direction. Taking the average of C and G gives the MPD in the direction perpendicular to the running direction, and taking the average of B, F and D, H gives the MPD in the direction 45° to the running direction. Obviously, taking the average from A to H gives the overall MPD.

This device uses a CCD (Charge Coupled Device) laser displacement sensor as a displacement sensor. This is positioned on an arm that rotates on a circular locus with a radius of 142mm at a position of 80mm above the road surface, and this arm is rotated by a DC motor. The measurement principle is to sense the unevenness of the road surface at a pitch of about 0.9 mm on a circular locus, convert the value to A/D, record it in memory, and measure 1,024 points per rotation. These values are processed by a computer, one rotation is divided into 8 sections, and the MPD for each section is calculated.

Conceptual Diagram of Measurement System

| Leather head | → | Amplifier unit | → | AD converter | → | Personal computer | → | Data output |

|---|---|---|---|---|---|---|---|---|

|

¦ |

↑ | |||||||

|

Rotary Encoder |

→ |

––––––––––––– Sampling signal |

↑ |

Main Specifications

| Size | 400 mm (D) x 400 mm (W) x 270 mm(H) |

|---|---|

| Weight | Net weight - 13 kg |

| Body + case weight - 24 kg | |

| Displacement sensor | CCD laser displacement sensor |

| Laser measurement range | 30 mm (65~95) |

| Laser spot diameter | φ70 μm |

| Wavelength | 670 nm |

| Resolution | 3 μm |

| Measuring circle radius | 142 mm |

| Number of samples per rotation | 1024 |

| Sampling interval | 0.9 mm (±0.05 mm) |

|

1 rotation is divided into 8 divisions, data processing for each division |

|

| Number of samples per segment | 128 |

| Rotation speed | 6 m/min |