Piolas

Overview

An olefin sponge with excellent liquid absorption that can be used with strong acid or strong alkaline liquids.

Characteristics

■In addition to resistance to strong acids and strong alkalis, it can also be used with oxidizing agents and some solvents.

■It is suitable as absorption, holding material of various liquids.

■As it is an integral structure, there is no fluffing or shedding unlike the fiber type.

■In addition to filter applications, it can be applied to various applications using fine continuous pores.

■By minute continuous pore structure, we show superior liquid absorptivity.

■As it is a soft sponge, it has excellent followability to the workpiece.

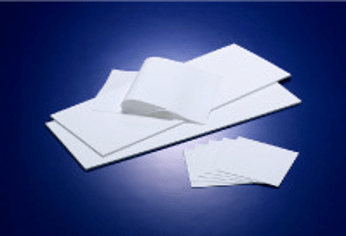

Piolas Sheet

Application

■Filtration and absorption of gasses and liquids

■Liquid transition material (inspection kit)

■Spacers for electronic components

■Humidity adjustment material (liquid volatilization)

■Ink absorber, ink supply for stationery, etc.

■Wiping material

Material

Basic Physical Properties

Standard imensions

| PE |

: |

300 x 500 x 1~7 mm |

| EVA |

: |

100 x 500 x 1~7 mm |

*For other sizes, please contact us.

Chemical Resistance

| Test conditions: |

Judgment by soaking for 2 weeks at room temperature (about 20°C) |

| Judgment Criteria: |

○ = Strength retention rate of 80% or more and dimensional change rate of less than 5% |

|

△ = Strength retention rate of 60% or more and dimensional change rate of less than 10% |

|

× = Less than 60% strength retention or 10% or more dimensional change |

*Depending on the application and usage, please perform an immersion confirmation test in advance.

*Wash (according to the cleanliness control level) before use, depending on the application.

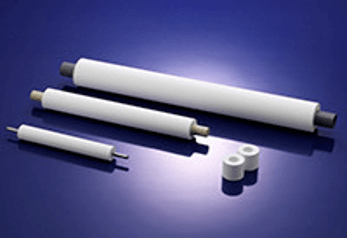

Piolas Roller

Application

■Plating and etching processes for printed circuit boards, lead frames, shadow masks, etc.

■Drainage, transport, and cleaning in the cleaning process of glass substrates for flat panels

■Draining, conveying, and applying chemicals in various manufacturing processes

Material:Polyolefin sponge

Basic Physical Properties

Roller Standard Size

| Outer diameter |

φ30 ~ 60 mm |

| Thickness |

15 mm以下 |

| Length |

1000 mm以下 |

*For other sizes, please contact us.

Chemical Resistance

| Test conditions: |

Judgment by soaking for 2 weeks at room temperature (about 20°C) |

| Judgment Criteria: |

○ = Strength retention rate of 80% or more and dimensional change rate of less than 5% |

|

△ = Strength retention rate of 60% or more and dimensional change rate of less than 10% |

|

× = Less than 60% strength retention or 10% or more dimensional change |

*Depending on the application and usage, please perform an immersion confirmation test in advance.

*Wash (according to the cleanliness control level) before use, depending on the application.