Electrode Manufacturing Equipment

Product Name

Electrode Manufacturing Equipment

Equipment for manufacturing electrode plates (positive and negative electrodes) for lithium-ion secondary batteries.

Detailed Explanation

Lithium-ion secondary batteries come in cylindrical, square, and pouch (laminate) types depending on the end use. The electrode manufacturing methods and equipment used in the battery types are also different. We can handle all battery types and provide comprehensive solutions by designing production lines to meet diverse customer needs.

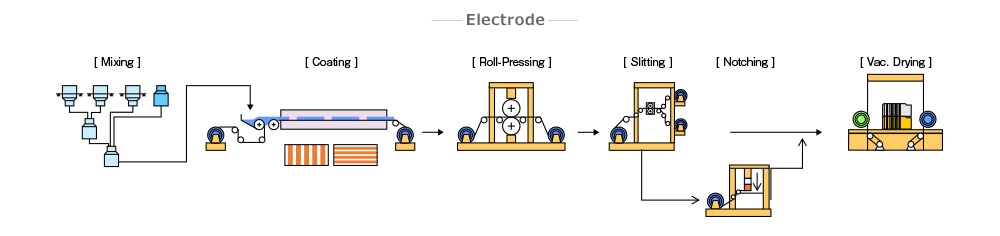

Electrode Production Line Overview

Main Electrode Production Line Configuration

| 1)Mixer | Manufacture electrode slurry by mixing positive electrode active material, binder, organic solvent, dispersant, etc. |

|---|---|

| 2)Coater | Apply electrode slurry to copper foil or aluminum foil. |

| 3)Slitter | Cut to a certain width according to battery specifications. |

Illustration

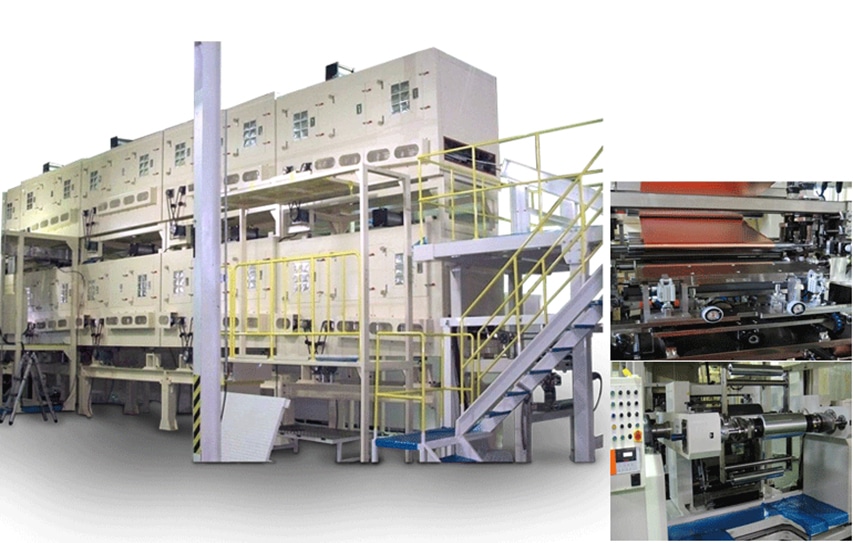

Product Specifications

| Coating Width | Max.650mm |

|---|---|

| Coating Accuracy | ±1.5%(Dry) |

| Machine Speed | Max.650m/min |

| Drying Type | Roll Supporting Type |

| Coating Speed | 0.5-20m/min |

| Drying Zone | 3m×5zone×2Floor=30m |

| Coating Type | Micro Gravure Type |

| Heating Source | Electric Heater |

| Coating Mode | Continuous & Intermittent |

| Dimension | 35.0m(L)×5.8m(W)×6.0m(H) |

| Coating Thickness | Max.20㎛(One Side) |

| Delivery | 6 months |

Contact: Mobility Materials Equipment, Tokyo(03-3546-3361)