Superhydrophilic Inorganic Coating Agent

CeraAqua NS Coat

Product Name

Superhydrophilic Inorganic Coating Agent

CeraAqua NS Coat

Overview

A super-hydrophilic polysilicate-based inorganic coating agent with excellent weather resistance, antifouling properties, and high transparency. Due to its self-cleaning effect and antistatic effect, for antifouling purpose, CeraAqua can be applied to outdoor structures like solar panels as well as exterior walls of buildings. Easy to apply with excellent workability due to its low viscosity.

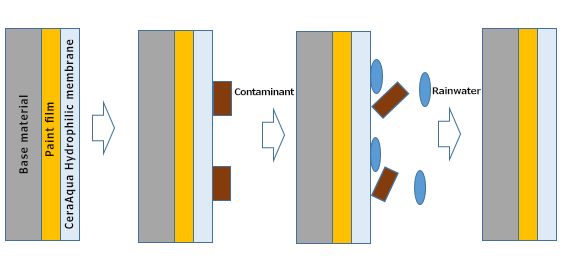

Mechanism

By applying a thin layer of polysilicate-based ceramic coating agent "CeraAqua" to the base material, the silanol groups of CeraAuqa are strongly bonded to the base material, forms a hard film and creates a super-hydrophilic antifouling film.

Characteristics

(1) Antifouling

Painted surfaces, tiles, glass, and metal surfaces that are used outdoors become discolored due to dirt in the atmosphere. CeraAqua performs self-cleaning effect(due to its hydrophilicity) by rainwater, etc., and restores substrate to its original beauty.

【Image diagram】

CeraAqua's hydrophilic film formed on the painted surface removes the attached dirt with rainwater.

(2) Weather resistance

CeraAqua is a polysilicate-based inorganic coating agent, it forms a highly light-transmitting inorganic coating layer that is insoluble in water and is extremely stable against UV and IR rays, so it does not cause discoloration or decrease in light transmittance.

(3) High transparency/light transmission

CeraAqua has a low refractive index and high light transmittance, which improves the transparency of glass, and the other transparent substrates.

(4) Easy workability

CeraAqua has a low viscosity and excellent applicability, as well as good adhesion to substrates.Usually cures in a short time at room temperature, also can be heat cured for shorter curing time.

Antifouling test

(1) Accelerated testing of antifouling materials for transparent plates (Public Works Research Center)

An antifouling test result of transparent plates for roads, conducted by the Public Works Research Center.

We applied a standard black contaminant to glass substrate coated with CeraAqua, dried it by heating, and sprayed water to remove contaminants, then measured the light transmittance and color difference of the glass. The results are as follows.

| Standard value | Test result | |

|---|---|---|

| Color difference | △L - 3.20以上 | △L - 0.68 |

| Transmittance | 66.0以上 | 94.2 |

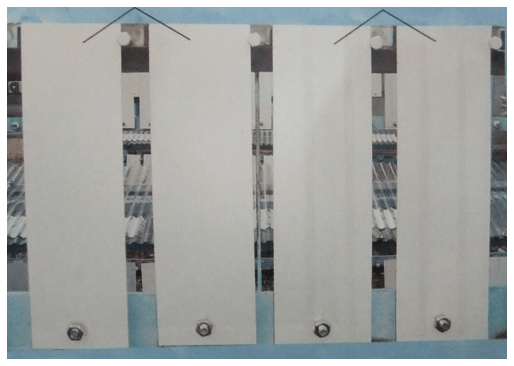

(2) Outdoor exposure and antifouling by raindrops test of coated steel sheet

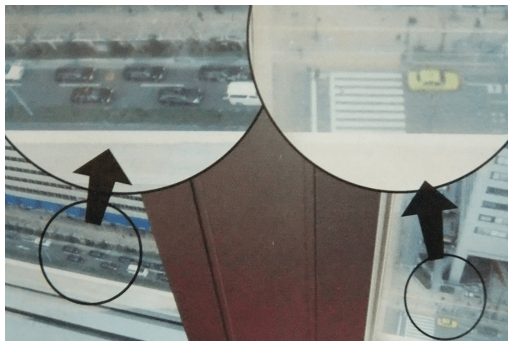

(3) Improved antifouling when applied to window glass

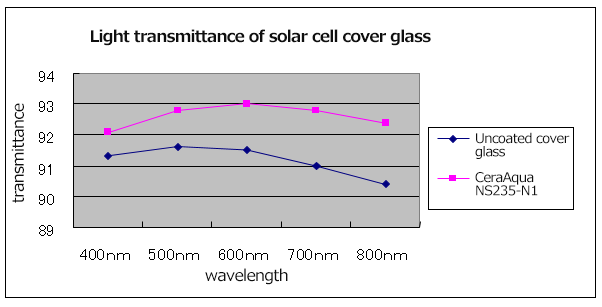

Light Transmission Test

Solar cell cover glass treated with CeraAqua (polysilicate ceramic coating) has improved light transmittance compared to uncoated cover glass.

| Coating agent | :CeraAqua NS235-N1 |

| Film thickness | :dry film thickness 0.3μm |

| Measuring instrument | :UV/visible spectrophotometer V530 (manufactured by JASCO Corporation) |

| Wavelength (nm) | 400 | 500 | 600 | 700 | 800 |

|---|---|---|---|---|---|

| Uncoated cover glass | 91.3% | 91.6% | 91.5% | 91.0% | 90.4% |

| CeraAqua coated glass | 92.1% | 92.8% | 93.0% | 92.8% | 92.4% |

Water Resistance Test

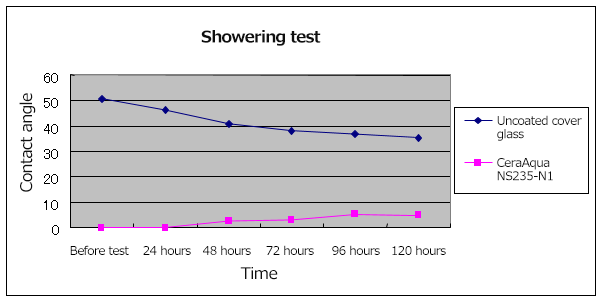

Showering test (pump: 70ml/cm2/minute water discharge)

Shower at 4,000ml/cm3/hour, that is, 4,000mm of precipitation per hour.

(*Reference: Annual precipitation in Osaka is 1,200 - 1,300 mm)

The change in contact angle of solar cell cover glass coated with CeraAqua NS235-N1 is shown below.

| Water discharge time | Before test | 24hours | 48hours | 72hours | 96hours | 120hours |

|---|---|---|---|---|---|---|

| Uncoated cover glass | 50.6 | 46.3 | 40.7 | 38.2 | 36.6 | 35.5 |

| CeraAqua coated glass | - | - | 2.5 | 3.0 | 5.3 | 5.0 |

Note: (-) indicates inability to measure with a contact angle meter.

Application Example

- Metal-based and ceramic-based exterior wall paints, tiles, etc.: Protection of base materials by coating on paint, antifouling effect by self-cleaning effect, anti-fouling effect by anti-static

- Architectural glass: Reduces cleaning frequency by applying antifouling to the exterior.

- Solar cell cover glass: improves and maintains the light transmittance due to antifouling and low refractive index.

- Window glass for automobiles, trains, etc.: Improved light transmittance due to hydrophilicity, long-term antifouling properties

- Mirror: Anti-fogging due to superhydrophilicity

- Antifouling for cover glass of street lights and lighting fixtures (LED, etc.)

- Antifouling of soundproof walls for roads (metal, acrylic, polycarbonate, etc.)

Construction Example

A house coated with CeraAqua NS235-N1 to prevent stains on the exterior paint (acrylic silicone paint)

Construction site where CeraAqua NS235-N1 is applied to a house with an air spray

Application Method

■Glass substrate

Lightly polish the glass surface with an abrasive (ceria slurry, alumina slurry, etc.) to remove dirt adhering to the surface, or scrape the glass surface slightly to expose the active surface, wash with water and dry completely.

■Surface treatment of exterior building materials

Wash the organic coated surface with a hot water high-pressure washer and dry it thoroughly.

If there are cracks in the painted surface, use Primer G130 to fill the cracks.

■Film base preparation

Corona treatment or primer treatment. The effect fades with time, so apply as soon as possible after treatment. Use our recommended CeraAqua Primer G130 as the primer.

■Coating tool

Roll coater, flow coater, air spray, sponge roller, brush

■Coating conditions

|

Application amount |

:30μm(wet film thickness) |

| Curing temperature | :Room temperature to 200°C x 5 minutes |

| Film thickness | :0.3μm or less (dry film thickness) |

Product Details

■Product name

1.CeraAqua NS235-N1

2.CeraAqua NS244-N1.5

■Ingredients

1.Inorganic component : Silica composite of polysilicate condensate

2.Solvent : Alcohols, propylene glycol ethers

■Properties

| Appearance | :Colorless transparent liquid |

| Specific gravity | :0.85~0.89 |

| Viscosity | :1~3mPa・s |

| Solid content | :0.9~1.6% |

■Dangerous goods classification

Class 4, type 1 petroleum

■Storage stability

3-6 months from date of manufacture

R&D center

In order to meet the needs of each customer's site, we have established an R&D center to develop materials under various conditions.

Please let us know your opinions and requests.