Optimizing material designs with advanced

measurement technology

Point

- As the development of electric vehicles (EVs) expands, there will be a growing need for lubricants, additives and automotive parts with enhanced functions.

- Shima Trading imports and sells testing systems capable of quantifying friction characteristics during sliding motion. As engineers, we also provide integrated technical support.

- We are helping to improve the environmental performance of automobiles by developing optimized lubricant and additive packages under conditions that mimic environments in actual machines as closely as possible. We plan to offer this technology for use in the development of other types of products, such as cosmetics and artificial joints, as an alternative to traditional methods based on human sensory input.

Related SDGs

Key Person

Industrial Energy Division

Lubricants & Additives Department

Masanori Kojima specializes in metallic complex chemistry. He wanted to use the knowledge that he had gained at university and initially took a job with a laboratory equipment trading company. However, he switched to Shima Trading in 2015 because of his strong desire to work with machines rather than consumables. After being assigned to work with tribology testing equipment, he gained a first-hand appreciation of the need for basic scientific knowledge as well as engineering knowledge and expertise based on frontline needs. Tribology is a composite field consisting of knowledge from every branch of science. Every day is a learning experience for Kojima, who joins scientific conferences and other events in addition to his normal work.

Optimizing Lubricants for the EV Revolution

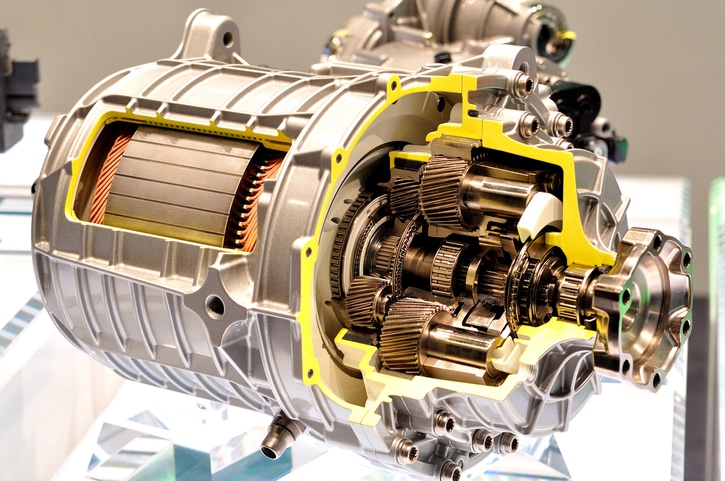

Lubricants are used to prevent friction by creating a thin film between objects that are sliding and rolling against each other. These substances extend the life of automotive engine components and play a key role in improving fuel efficiency. However, lubricants and additives need to be adjusted carefully, since if their viscosity is too high, they will cause resistance, while if it is too low it will impossible to maintain an oil film, possibly resulting in damage to components.

Conventional lubricants were developed for use in internal combustion engines, such as automotive engines. The rush to develop EVs is creating a growing need for high-performance lubricants formulated for applications other than internal combustion engines. As a result, testing under high-speed/high-load conditions has become increasingly important.

Evaluation using lubricant testing systems now the global standard

In 2004 Shima Trading began to sell a variety of tribology testing equipment after becoming the exclusive import and maintenance agent for tribology equipment manufactured by the British company PCS Instruments. These systems can simulate a variety of friction assessment situations. EHD oil film thickness testers can measure the thickness of oil films on sliding parts at the nanometer* level. These systems are used in the development of lubricants and additives for the automotive industry. However, they are also increasingly in demand for use in the assessment of component coatings. We are currently promoting new tribological applications, including the proposal of solutions for the cosmetics industry.

*Nanometer: A unit of length equivalent to one-millionth of a millimeter.

Key Point

Tribology testing equipment has become the standard in the lubricant industry because of the need to assess the friction properties of lubricants used in the automotive industrial market. Their role is not limited to the automotive industry. For example, in the cosmetics industry the friction properties of base preparations are generally assessed using sensory testing by human beings. We believe that manufacturers need a way to turn these evaluations into precise quantitative data that can be shared and used to improve product performance and reduce material losses.

As I consider these future possibilities in my sales activities, I am frequently reminded of the importance of scientific knowledge. After-sales support is vital for these systems, and I know that I have earned the trust of customers when they ask me about devices for particular applications. That is why I monitor industry trends and gathers information and knowledge about related technologies through conferences and other events.